Backbone Road RESTITUTIO: Tungsten Carbide Road Milling Tools

Industria News-Infrastructura hodiernae civilizationis gravis reticulis in via bene conservata nititur. A discrimine processus in hac sustentatione exolvuntur est via milling (etiam nota frigida plani vel profiling), quae involvit remotionem pavimenti cacuminis exsistentis ad superficiem unifor *mem praeparandam ad novam bitumen vel concretam applicationem. Integrum efficientiae et cost-efficentiae huius operationis sunt Tungsten Carbide Road Milling Tools .

Materia unica: Carbide Wolframium

Tungsten carbide ($\text{WC}$) is a composite material, often referred to as a “cemented carbide,” comprising fine particles of tungsten carbide bonded together by a metallic binder, most commonly cobalt ($\text{Co}$). This unique combination results in a material that boasts exceptional properties, making it an ideal choice for the extreme demands of pavement removal.

- Extrema duritia: Duritiem carbidi Tungsten, secundum adamantem solum, eam permittit ut efficaciter per matricem asphaltitae laesurae secetur et sine cito hebetatione lapidum aggregatur.

- Superior gere resistentia; Materia constanti resistit, summus velocitas abrasionis in millo offendit, signanter instrumentum vitae ad instrumenta ferri tradita comparata.

- Princeps Compressive fortitudo: Potest sustinere immensas copias et onera ictum generatorum cum strato rotato milling tympani durae molitur.

- Calor stabilitas: Duritiam incisionis acutae criticae conservat, sicut attritio alta magnum calorem generat.

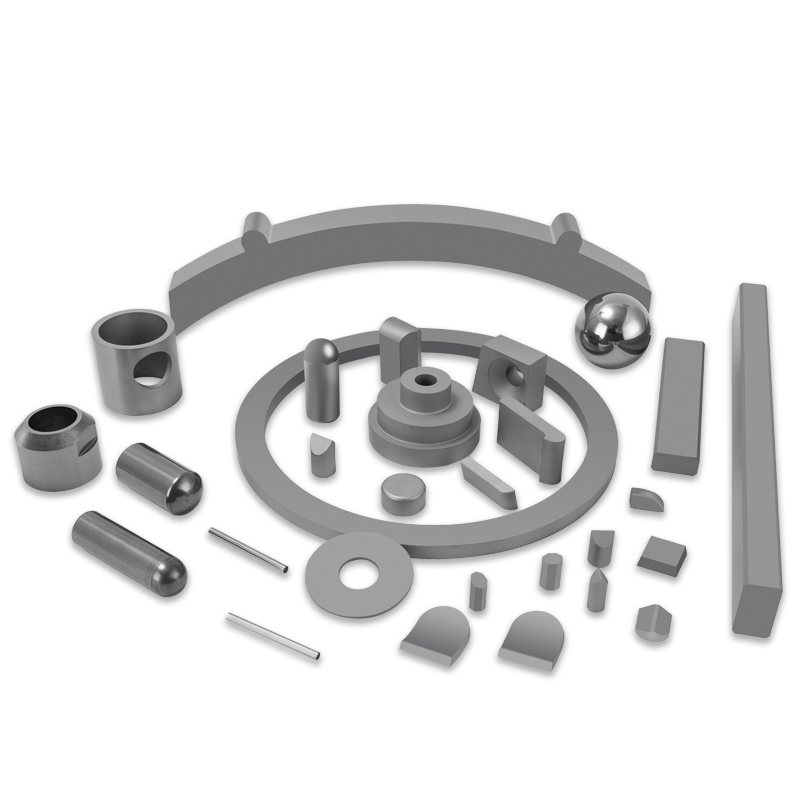

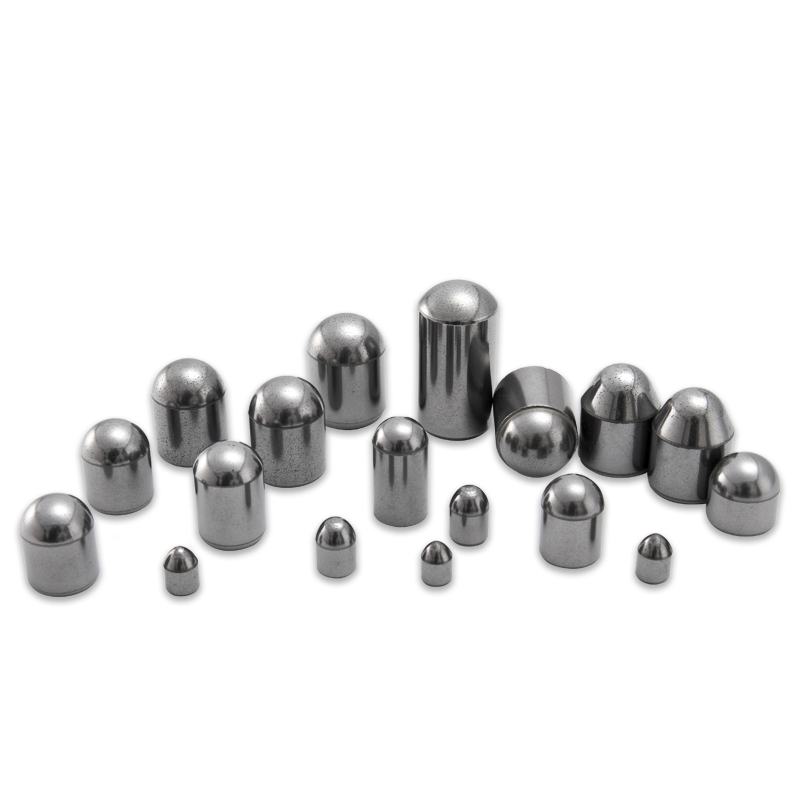

Anatomia Instrumentorum Milling

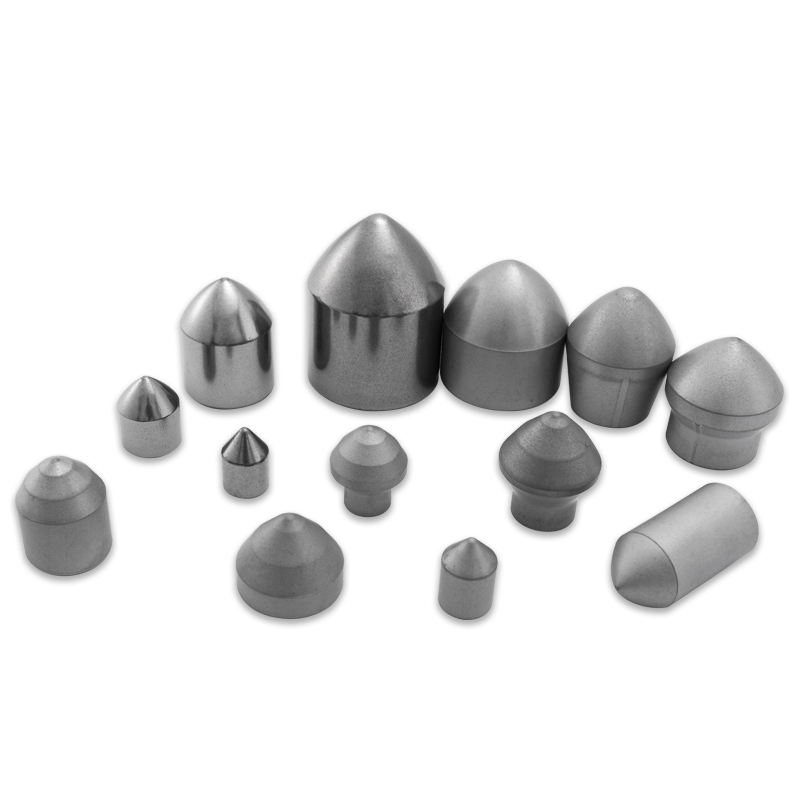

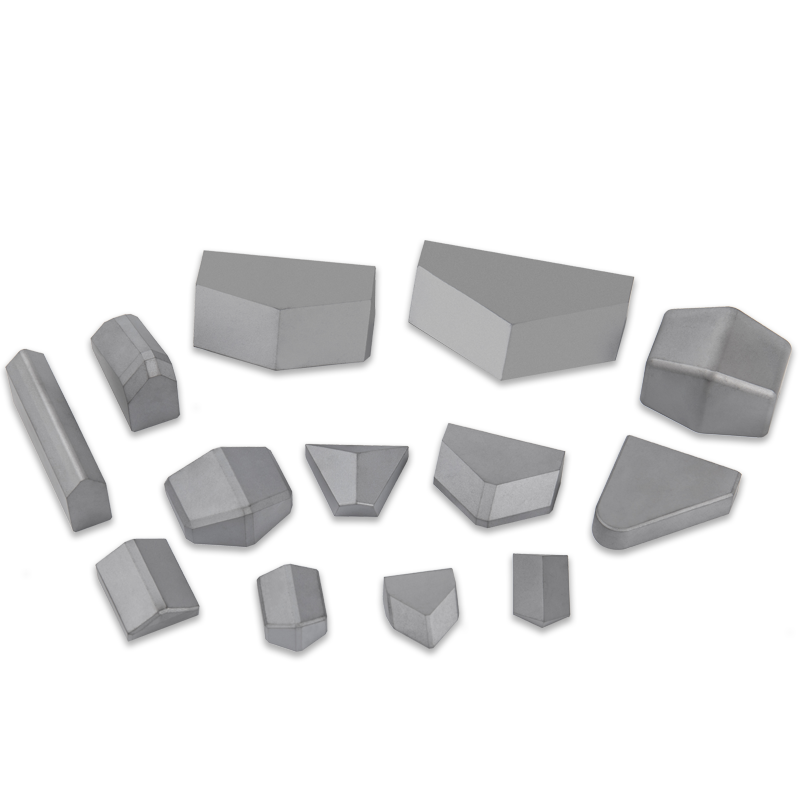

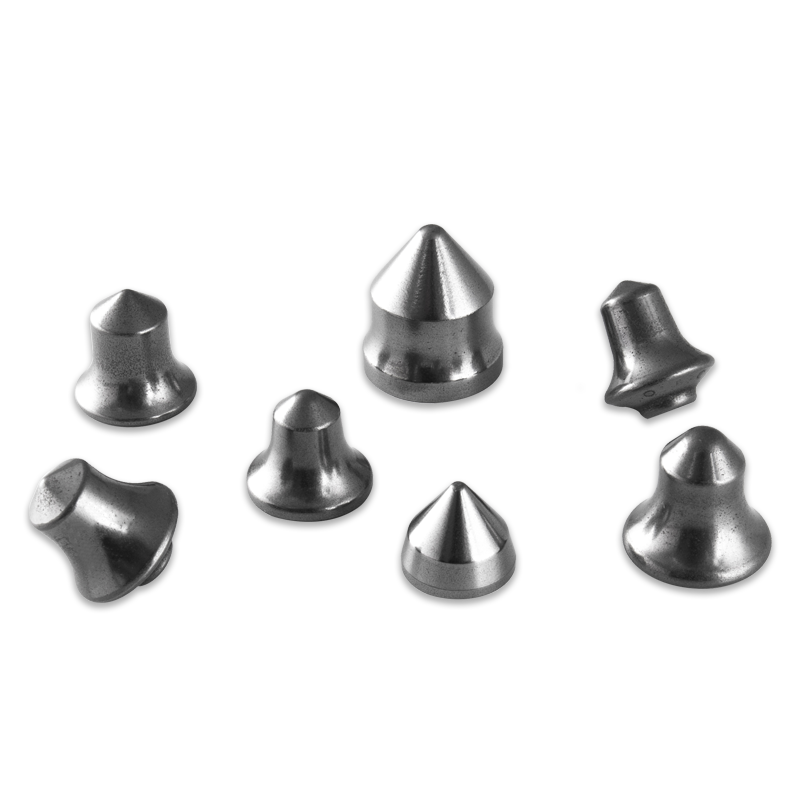

Primarium instrumentum in processus milling usus est conica sectione paulum or colligunt . Dum specificum consilium per fabrica et applicatione variat (exempli causa, bitumen vs. concretum), omnia efficax Tungsten Carbide Road Milling Instrumenta nucleum communicant structurae ad perficiendum machinatum;

- Carbide consilium: This is the working head of the tool, typically sintered tungsten carbide. Its grade (determined by $\text{WC}$ grain size and cobalt content) is selected based on the material being milled—finer grains and lower cobalt for harder materials like concrete, and coarser grains and higher cobalt for toughness in asphalt.

- Steel Shank / Corpus: Hoc corpus robustum carbide extremum connectit ad instrumentum tenentem in tympano mill. Fortis et tenax debet esse ut impulsus et flexiones vires trahant sine fractione.

- Ratio retinendi: Sulcus vel collaris consilium permittit ut instrumentum gyrari in possessore ad lapsum se acuere ac celerem mutationem functionis permittit ad substitutionem celeri cum aliquantulum teritur vel laeditur.

Operational Beneficia in Road RESTITUTIO

Adoptio Tungsten Carbide Road Milling Tools fundamentaliter viam emendavit industriae rehabilitationis, directe vertendo in beneficia tangibiles oeconomicos et operationales;

| Beneficium | Descriptio | Impact in Projects |

|---|---|---|

| auctus Productivity | Instrumenta acutam aciem secantis longioris conservant, permittentes machinis celeritatibus constantibus et rates remotionis superiores operari. | Velocius project complementum et reducuntur apparatus operating horis. |

| Reducitur Downtime | Pauciores instrumentorum mutationes requiruntur in profesto tempore melioris vitae induendi. Systema vivum mutare adhuc tempus minimize quod ad victum necessarium est. | Maximized on-site opus tempore et demittere laborem gratuita pro instrumento operandi. |

| Lower Custus-Per-Quadratum area | Dum initialis instrumenti carbidi fistulae sumptus altior est quam chalybe, eius scenica vitae spatium extenditur et efficientia meliore ducunt ad summam inferiorem sumptus super vitae documenti. | Improved project profitability et ipsum nibh elit. |

| Superficiem consistent Quality | Persecutio sustentata secans aequabilem superficiem molitam (profile) efficit, quae pendet vinculo et longivitate novi strati pavimenti. | Qualis altior via superficiem finalem et minus piget opus. |

Acta et Future Outlook

Industria pergit innovare, in optimizing microstructure tungsten carbidi materialis. Progressiones modernae includunt:

- Nano-Technologia Carbide: Augmenta ad cobaltum ligans matrix ad duritiem optimizandam et resistentiam ad nanoscale induendam, ducens ad frena etiam flexibilia et durabilia.

- Improved Brazing Techniques: Meliora methodi ligandi in carbide tip ad chalybem scapus ne praematura defectum ob ictum et scelerisque lacus.

- Propria Geometria: Progressus singularis apices formarum et magnitudinum ad provocationes specificas, sicut pavimenta graviter canaliculata vel concreta ultra-dure.

Sicut via retiaculorum aetas et postulatio efficientis, summus qualitas pauimenti sustentationem auget; Tungsten Carbide Road Milling Tools technologia necessaria manebit, efficientiam ac sustineri posse in global constructione et infrastructura regione. .